Get a custom solution for free

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

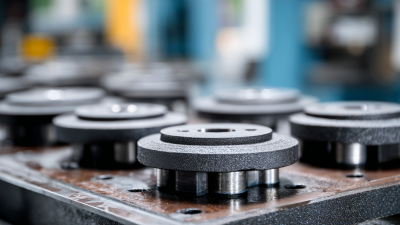

In the realm of industrial applications, the choice of supporting structures is critical for enhancing operational efficiency and longevity of machinery. One of the most effective solutions to consider is the use of Rubber Mounts. These versatile components offer a multitude of benefits, ranging from vibration reduction to improved safety. As industries continue to demand higher performance and reliability from their equipment, Rubber Mounts emerge as a crucial element in mitigating the stresses faced by machinery.

In this blog, we will explore the top advantages of utilizing Rubber Mounts, detailing the reasons why they are an indispensable asset for modern industrial environments. From their ability to absorb shocks and vibrations to their cost-effectiveness and durability, understanding the significance of Rubber Mounts can lead to smarter engineering choices and enhanced operational outcomes.

Rubber mounts are increasingly recognized for their effectiveness in vibration isolation across various industrial applications. Their unique properties allow them to absorb shock and dampen vibrations, which is crucial for maintaining equipment integrity and enhancing user comfort. In sectors like manufacturing and transportation, the use of rubber mounts can significantly reduce wear and tear on machinery, ensuring longer operational lifespans and minimizing maintenance costs.

The benefits of rubber mounts extend beyond simple vibration damping. Their ability to provide low natural frequencies makes them ideal for isolating vibrations from sensitive machinery, such as ultra-precision machine tools, where even slight interference can compromise performance. Moreover, innovations in rubber formulations, such as those incorporating rice husk silica, are improving dynamic properties and enhancing the effectiveness of these mounts, leading to even better vibration isolation. As industries continue to prioritize efficiency and reliability, rubber mounts will play a pivotal role in the evolution of vibration control solutions.

Rubber mounts have become increasingly vital in various industrial applications due to their remarkable ability to enhance durability and extend the lifespan of equipment. By effectively dampening vibrations and shocks, rubber mounts protect sensitive machinery from wear and tear caused by constant operational stress. This not only reduces maintenance costs but also minimizes downtime, allowing industries to maintain consistent productivity levels.

Recent advancements in rubber technology have further contributed to the longevity of equipment. Innovations in materials and production techniques enable rubber mounts to withstand harsher conditions and provide better performance in high-stress environments. For instance, improved anti-vibration solutions are essential in sectors such as shipbuilding, where the demands on structural integrity and performance are critical. These enhancements demonstrate the significant role that rubber mounts play in extending the lifespan of not only industrial equipment but also infrastructure components like offshore wind turbines, where prolonged durability is crucial for sustainability and efficiency.

| Parameter | Description | Impact on Equipment Lifespan |

|---|---|---|

| Vibration Absorption | Reduces transmission of vibrations from machinery | Minimizes wear and tear on components |

| Noise Reduction | Dampens sound produced by machinery | Creates a quieter working environment |

| Shock Isolation | Absorbs shocks from sudden impacts | Protects sensitive equipment from damage |

| Chemical Resistance | Resistant to various industrial chemicals | Prevents degradation of mounts, prolonging life |

| Temperature Tolerance | Can withstand extreme temperature fluctuations | Ensures consistent performance over time |

Rubber mounts play a crucial role in reducing noise and vibrations in industrial settings, contributing significantly to overall operational efficiency. By isolating machines from their surroundings, these mounts help in minimizing the transmission of noise, which is essential in maintaining a safe and productive work environment. This is particularly important in industries like manufacturing, where excessive noise can lead to worker fatigue and decreased productivity. Furthermore, a quieter workplace can enhance communication among employees, leading to better teamwork and coordination.

Rubber mounts play a crucial role in reducing noise and vibrations in industrial settings, contributing significantly to overall operational efficiency. By isolating machines from their surroundings, these mounts help in minimizing the transmission of noise, which is essential in maintaining a safe and productive work environment. This is particularly important in industries like manufacturing, where excessive noise can lead to worker fatigue and decreased productivity. Furthermore, a quieter workplace can enhance communication among employees, leading to better teamwork and coordination.

When incorporating rubber mounts into your industrial applications, consider the following tips. First, ensure that you select the right type and size of rubber mount for your specific machinery, as this will optimize vibration absorption. Second, regularly inspect and maintain the mounts to avoid deterioration over time, which can lead to increased noise and reduced effectiveness. Lastly, consider using multiple mounts strategically placed to create an efficient vibration isolation system that enhances overall productivity and safety.

Investing in quality rubber mounts not only minimizes disruption from noise but also protects equipment from the damaging effects of vibration. In a world where the global automotive bushing market is projected to see significant growth, leveraging these mounts can be a strategic decision for industries aiming to elevate their operational standards and maintain competitive advantage.

When selecting the right rubber mount for industrial applications, several design considerations come into play. Firstly, it’s essential to understand the specific requirements of the equipment it will support, including load capacity, frequency of vibration, and environmental conditions. Different rubber compounds can offer varying degrees of durability, flexibility, and resistance to elements such as oil or extreme temperatures, making the material selection crucial for optimal performance.

Another critical factor is the mount's design configuration. Rubber mounts come in various shapes and sizes, each designed to handle specific types of loads and vibrations. For instance, you might prefer a cylindrical mount for rotational support or a customizable design to meet unique space constraints. Furthermore, it’s important to consider the mount's ability to accommodate dynamic movements, as well as the installation process. Ensuring that the chosen mount fits seamlessly into the existing framework can mitigate potential issues and enhance overall equipment stability, leading to improved operational efficiency.

Rubber mounts have increasingly become an essential component in various industrial applications, especially considering their cost-effectiveness. As industries face rising material and labor costs due to economic fluctuations and tariffs, the use of rubber mounts can provide significant savings in operational expenses. By reducing vibrations and impacts in machinery, rubber mounts not only enhance equipment longevity but also minimize maintenance costs, which can significantly affect a company's bottom line.

The growing shipbuilding anti-vibration market, projected to expand to $1,684.1 million by 2032, exemplifies the economic benefits of integrating rubber mounts. With a compound annual growth rate (CAGR) of 5.8%, the demand for effective vibration-dampening solutions underscores the economic advantages that rubber mounts offer. This trend demonstrates a broader recognition within industries of the financial and operational efficiencies that come with adopting such technologies. As industries continue to innovate, rubber mounts represent a smart investment that aligns with both economic resilience and sustainable practices in material usage.