Get a custom solution for free

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

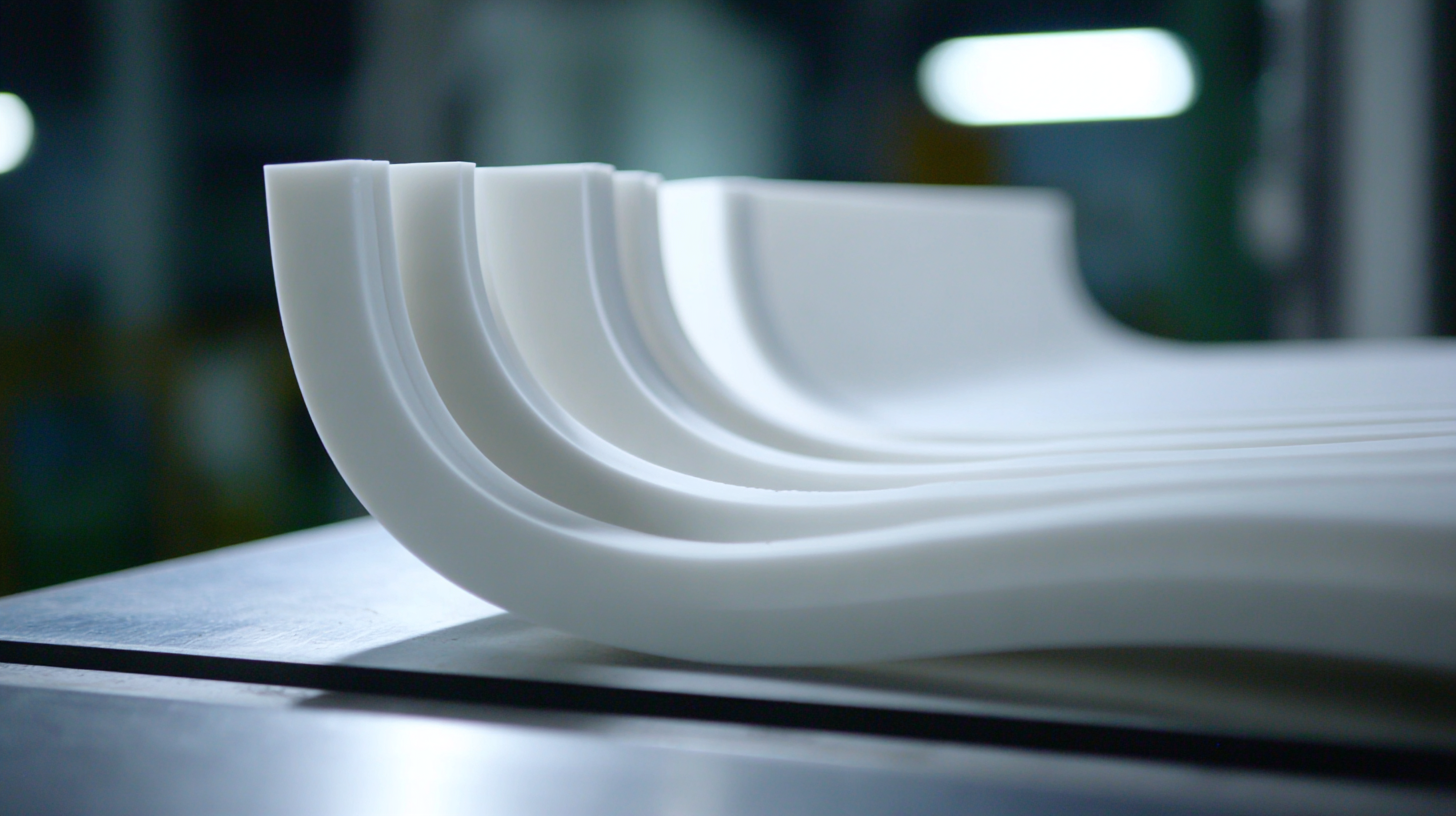

In the ever-evolving landscape of manufacturing, the incorporation of advanced technologies in Molded Rubber and Plastic has proven to be a game-changer for various industries. Recent industry reports indicate that the global rubber and plastic product market is expected to reach $800 billion by 2025, with molded solutions playing a critical role in this growth. Innovations in molded materials not only enhance product durability and performance but also contribute to significant cost reductions and efficiency gains.

By leveraging state-of-the-art techniques such as 3D printing and smart molding processes, businesses can tap into new opportunities for customization and sustainability. As we explore the 7 Best Molded Rubber and Plastic Innovations, it becomes clear that these advancements are not just trends; they are essential strategies for remaining competitive in today's market.

Molded rubber has revolutionized manufacturing processes across various industries, offering innovative solutions that enhance product durability, flexibility, and performance. According to a recent report by Grand View Research, the global molded rubber market is projected to reach USD 39.37 billion by 2026, growing at a CAGR of 4.6%. This growth highlights the increasing adoption of molded rubber in applications ranging from automotive parts to consumer goods, driven by the demand for lightweight and resilient materials.

Incorporating molded rubber into manufacturing can significantly improve production efficiency. For instance, rubber gaskets and seals provide excellent resistance to oils and chemicals, which is crucial in industries like aerospace and pharmaceuticals. Tips for businesses looking to implement molded rubber solutions include considering the specific application requirements and engaging with suppliers who specialize in custom molding technologies. Establishing a robust testing protocol can also ensure that the selected materials meet the necessary performance standards.

Furthermore, advancements in plastic molding techniques have complemented molded rubber innovations, enabling manufacturers to produce complex designs with precision. According to the Plastics Industry Association, the U.S. plastics industry produced $382 billion in shipments in 2020, demonstrating the critical role this sector plays in driving innovation. To maximize the benefits, businesses should stay informed about the latest trends and technologies, leveraging resources such as industry trade shows and webinars to enhance their manufacturing capabilities.

Sustainable practices in molded plastic production are becoming increasingly essential for modern businesses aiming to minimize their environmental impact. By adopting eco-friendly materials and processes, companies can significantly reduce waste and energy consumption. Innovations in recycled rubber and plastic formulations are paving the way for the development of products that not only meet high-performance standards but also address the pressing need for sustainability. For instance, utilizing biodegradable additives in the molding process can enhance the lifespan of products while ensuring they are less harmful to the environment once disposed of.

Sustainable practices in molded plastic production are becoming increasingly essential for modern businesses aiming to minimize their environmental impact. By adopting eco-friendly materials and processes, companies can significantly reduce waste and energy consumption. Innovations in recycled rubber and plastic formulations are paving the way for the development of products that not only meet high-performance standards but also address the pressing need for sustainability. For instance, utilizing biodegradable additives in the molding process can enhance the lifespan of products while ensuring they are less harmful to the environment once disposed of.

Additionally, implementing closed-loop manufacturing systems allows businesses to reprocess scrap materials and reduce the reliance on virgin plastics. This practice not only conserves resources but also lowers production costs, creating a win-win situation for manufacturers and the planet. By investing in advanced technologies that promote recycling and waste reduction, companies can enhance their reputation as environmentally responsible entities while appealing to a growing consumer base that prioritizes sustainability. Adopting these practices ensures that molded rubber and plastic production aligns with the evolving demands of modern society, ultimately fostering a more sustainable future.

When it comes to enhancing product durability, advanced molded rubber materials offer unique advantages that significantly improve a business's bottom line. According to a report by Freedonia Group, the global molded rubber market is projected to reach $28.4 billion by 2025, highlighting the increasing demand for these materials across various industries. The versatility and robustness of molded rubber allow it to withstand extreme conditions, thereby extending the lifespan of products in sectors ranging from automotive to aerospace.

Companies exploring molded rubber innovations should consider implementing strategies that emphasize quality. For instance, investing in high-performance compounds can enhance resistance to wear and tear, ensuring products can maintain their integrity under stress. Moreover, optimizing the molding process can lead to better material distribution and product consistency, further boosting durability.

Tip: Regularly evaluate your suppliers for the latest advancements in molded rubber technology. This practice not only keeps your products competitive but also allows you to leverage materials that offer superior performance characteristics. Additionally, consider conducting tests on molded rubber prototypes before mass production to ensure they meet your durability standards. This proactive approach can save time and resources in the long run.

Customization in molded plastic products is evolving rapidly, driven by industries’ unique requirements and technological advancements. According to a report by Smithers Pira, the global market for custom molded plastics is projected to reach $65 billion by 2025, highlighting the growing demand for tailored solutions across various sectors. Businesses are increasingly seeking products that not only meet functional specifications but also enhance brand identity. Customization in design, material selection, and production processes is essential for ensuring that the end product aligns perfectly with market needs.

Innovative techniques such as 3D printing and advanced materials technology have made it easier to create bespoke molded rubber and plastic products. These innovations enable businesses to reduce lead times and lower production costs while still achieving high levels of personalization. A report by Grand View Research indicates that the increasing focus on sustainability is further pushing companies to explore recycled and bio-based materials in their custom solutions, reflecting a broader trend towards eco-friendly practices. Emphasizing customization helps businesses stand out in a competitive market, catering to consumer preferences while leveraging the latest advancements in material and production technologies.

This chart illustrates the impact of various innovations in molded rubber and plastic products, highlighting their significance in customization, durability, cost efficiency, weight reduction, sustainability, design flexibility, and production speed. Each aspect is rated on a scale from 1 to 10 based on its perceived impact on business needs.

The injection molding market is set for significant growth, projected to increase from USD 365.22 billion in 2024 to USD 580.44 billion by 2033, showcasing a compound annual growth rate (CAGR) of 4.74%. This surge is largely driven by technological advancements, particularly in the medical sector where modernized molding techniques are essential for producing intricate components from high-performance materials. These innovations not only enhance production efficiency but also improve the precision and functionality of medical devices, catering to the evolving needs of the healthcare industry.

Moreover, the rubber molding market is also anticipated to see a steady rise, with its value estimated to escalate from USD 694.48 million in 2024 to USD 914.09 million by 2033. Events such as CHINAPLAS 2025, a major exhibition focused on plastics and rubber innovation, highlight the industry's commitment to embracing cutting-edge technologies and sustainability. As the global demand for rubber and plastic products continues to expand, these trends underscore the importance of innovation in shaping a resilient and efficient future for the industry.

| Innovation | Material Type | Application | Environmental Impact | Cost-Saving Potential |

|---|---|---|---|---|

| Recycled Rubber Mats | Recycled Rubber | Flooring Solutions | Low Carbon Footprint | High |

| Thermoplastic Elastomers (TPE) | TPE | Medical Devices | Biodegradable Options | Medium |

| Injection Molded Plastics | Polypropylene | Automotive Parts | Energy Efficient Production | High |

| 2K Injection Molding | Polyurethane | Consumer Goods | Reduced Waste | Medium |

| Bioplastics | PLA (Polylactic Acid) | Packaging | Renewable Sources | Medium |

| Silicone Molding | Silicone Rubber | Healthcare Products | Long Lifecycle | High |

| Foam Injection Molding | Polyurethane Foam | Furniture | Insulation Properties | Medium |