Get a custom solution for free

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

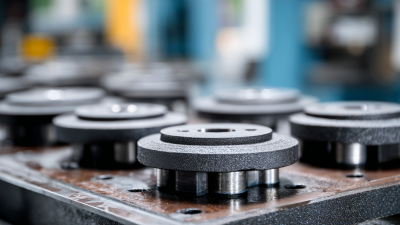

In the realm of industrial applications, the significance of effective vibration control cannot be overstated. One of the most crucial components in achieving optimal vibration management is the selection of appropriate Rubber Mounts. These essential elements serve as a buffer, isolating machinery from unwanted vibrations that can lead to mechanical failure, operational inefficiencies, and increased wear and tear. However, with a myriad of options available on the market, choosing the right Rubber Mounts can be a daunting task. This guide aims to provide a comprehensive overview of key factors that should be considered when selecting Rubber Mounts, ensuring enhanced durability and performance in various industrial environments. By understanding material properties, load capacities, and environmental influences, professionals can make informed decisions that will ultimately contribute to smoother operations and longer machinery life.

In industrial applications, effective vibration control is essential for maintaining equipment performance and improving overall operational efficiency. Understanding the basics of vibration control can significantly impact not just machinery longevity, but also workplace safety and productivity. By utilizing appropriate rubber mounts, industries can significantly attenuate vibrations caused by machinery, protecting both the equipment and the environment around them.

Tips: When selecting rubber mounts, consider factors such as the frequency range of the vibrations, weight load, and the mounting conditions. It's crucial to match the rubber mount specifications with the specific requirements of the equipment to achieve optimal results.

Moreover, continuous monitoring and maintenance play vital roles in vibration control. Deploy advanced vibration sensors to collect data on equipment performance, allowing for predictive maintenance and timely interventions. This proactive approach minimizes unexpected downtime and operational costs, reinforcing the importance of integrating vibration control measures into industrial practices.

Tips: Regularly evaluate sensor data to identify any trends or anomalies that could indicate potential issues, and adjust your vibration control strategy accordingly.

| Mount Type | Load Capacity (lbs) | Hardness (Shore A) | Operating Temperature (°F) | Damping Ratio |

|---|---|---|---|---|

| Standard Rubber Mount | 400 | 60 | -20 to 180 | 0.2 |

| Heavy-Duty Rubber Mount | 800 | 70 | -20 to 220 | 0.25 |

| High-Temperature Rubber Mount | 600 | 80 | -40 to 300 | 0.3 |

| Chemical-Resistant Rubber Mount | 500 | 75 | -20 to 180 | 0.18 |

When selecting rubber mounts for optimal vibration control in industrial applications, several key factors must be considered to ensure that the chosen mounts effectively minimize vibrations while supporting operational efficiency. One critical aspect is the load capacity of the rubber mounts. According to industry reports, such as the “Vibration Control Market Analysis,” understanding the load-bearing requirements can drastically impact performance. It’s essential to choose mounts that can handle both static and dynamic loads.

Another significant factor is the natural frequency of the rubber mounts. The natural frequency should be aligned with the vibration frequencies present in the application to maximize attenuation. A report from the "National Institute of Standards and Technology" highlights that mismatched frequencies can lead to resonance, exacerbating vibration issues rather than alleviating them.

Tips: Always conduct thorough testing with demonstration mounts before final selection. Additionally, consider the environmental conditions, such as temperature and exposure to chemicals, as these can affect the rubber's longevity and performance. Consulting with manufacturers about specific elastomer types can provide tailored solutions that enhance durability and functionality in industrial settings.

When evaluating different types of rubber mounts for industrial applications, it is crucial to consider the specific requirements of the application at hand. Various industries such as automotive, building and construction, and industrial manufacturing have unique vibration control needs. For instance, automotive applications may require rubber mounts with exceptional durability and the ability to withstand high-frequency vibrations, while in building and construction, mounts might need to cope with both structural loads and environmental factors.

Moreover, the material composition and design of rubber mounts play a significant role in their performance. Rubber mounts can vary in their hardness, damping properties, and resistance to temperature fluctuations, which affect their effectiveness in controlling vibrations. In industrial manufacturing, rubber mounts tailored to specific machinery can enhance operational efficiency by reducing noise and prolonging equipment lifespan.

Careful consideration of these factors will ensure that the right rubber mounts are selected, ultimately leading to improved stability and performance in various applications.

When selecting rubber mounts for optimal vibration control in industrial applications, understanding the load capacity and operational environment is crucial. Load capacity refers to the maximum weight that a rubber mount can support without failure, which varies significantly based on the material and design of the mount. For instance, high-performance elastomers can handle loads exceeding 1,500 lbs, making them well-suited for heavy machinery operations. Meanwhile, operational environments, such as temperature fluctuations and exposure to chemicals, must be considered, as these factors can affect the durability and effectiveness of the mounts over time.

**Tips:** Always refer to manufacturer specifications to ensure the chosen mount meets the load requirements of your application. Utilize software tools that simulate load conditions to evaluate the performance of different rubber mounts under expected operational stresses.

Another essential aspect is understanding how different vibration frequencies interact with rubber mounts. For example, mounts designed for high-frequency applications typically use softer compounds to dissipate energy effectively, while those for low-frequency applications might be firmer to maintain stability. Recent studies suggest that using a combination of both types in a system can enhance overall performance in environments with variable vibration profiles.

**Tips:** Consider conducting a thorough onsite analysis of vibration patterns before selecting rubber mounts. This data can help you choose the correct type of mount, leading to improved system longevity and performance.

Testing and maintenance practices are crucial to ensuring effective vibration control in industrial applications. Regular inspection of rubber mounts, for instance, helps identify wear and tear that could compromise their performance. Using diagnostic tools such as accelerometers can provide precise measurements of vibration frequencies and amplitudes, allowing engineers to evaluate the effectiveness of the installed mounts. Any abnormal readings may indicate that the mounts are either too soft or too stiff for the specific application, necessitating further investigation or replacement.

Scheduled maintenance routines, including cleaning and tightening of brackets and supports, are vital for prolonging the life of rubber mounts. In addition, maintaining an optimal environment around the mounts—free of excessive heat, oil, or other contaminants—can enhance their durability. Keeping detailed records of the testing and maintenance activities helps in tracking the performance of rubber mounts over time, ultimately leading to better decision-making regarding replacements or upgrades. By prioritizing these practices, industries can significantly improve their vibration control solutions, leading to enhanced equipment reliability and reduced operational costs.