Get a custom solution for free

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

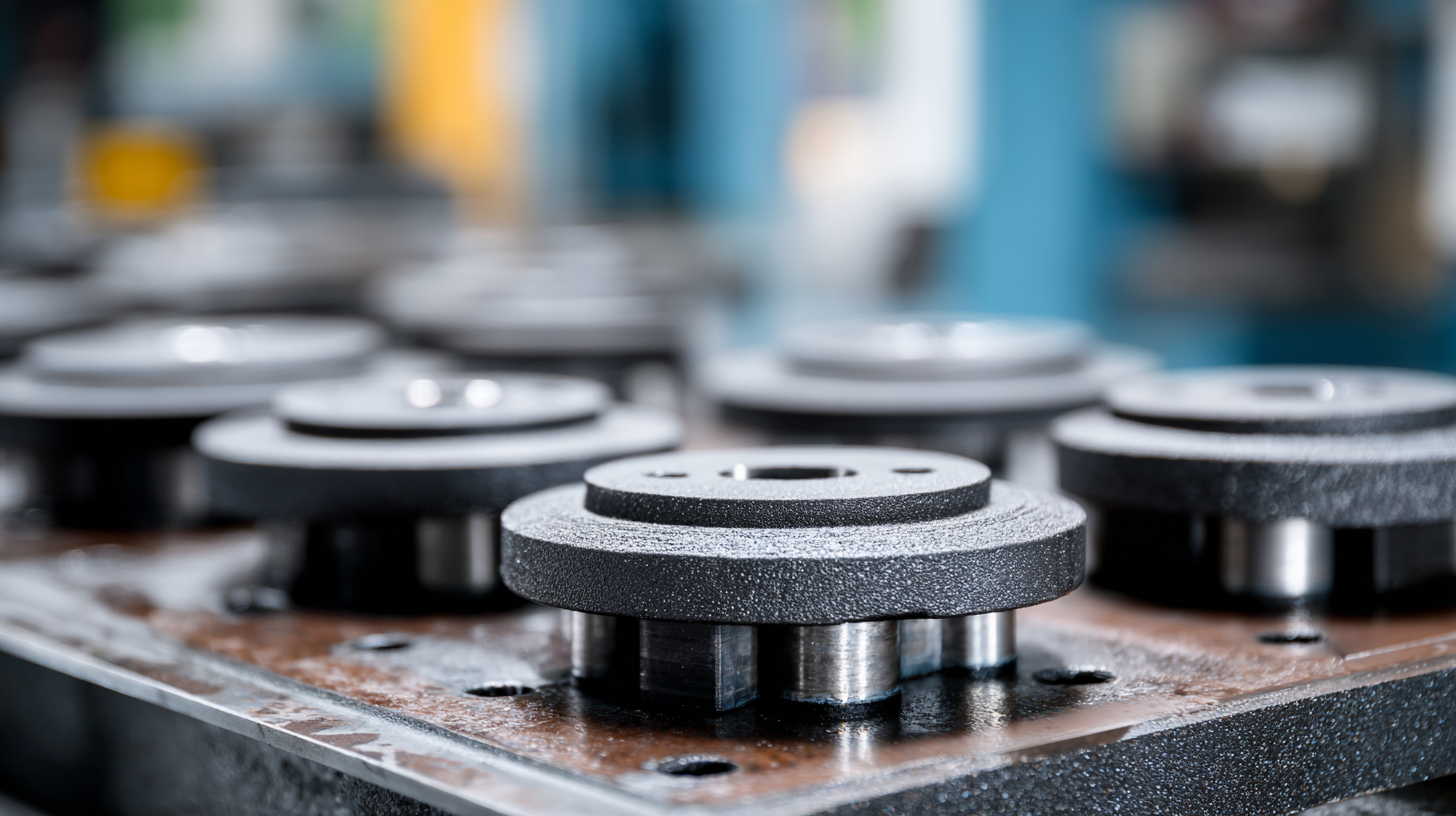

In various industries, the significance of Rubber Isolation Mounts cannot be overstated, as they provide critical support in minimizing vibrations, noise, and shock. According to a recent report by MarketsandMarkets, the global rubber mounts market is projected to reach $3.7 billion by 2026, growing at a 4.8% CAGR from 2021. This growth is largely driven by the increasing demand for innovative vibration control solutions across sectors such as automotive, aerospace, and manufacturing. These mounts play an essential role in enhancing the performance and longevity of machinery and equipment, while also contributing to safety and comfort. As industries continue to evolve, exploring the unique applications of Rubber Isolation Mounts reveals opportunities for improved efficiency and operational excellence in diverse contexts.

Rubber isolation mounts are vital components used across various industries for their unique features that enhance operational efficiency and safety. Notably, they are designed to absorb vibrations and shocks, protecting both machinery and workers. According to a report by MarketsandMarkets, the vibration isolation market is projected to reach USD 4.67 billion by 2026, reflecting a compound annual growth rate (CAGR) of 5.2%. This growth emphasizes the increasing reliance on rubber isolation mounts in sectors such as manufacturing, automotive, and construction.

One of the standout characteristics of rubber isolation mounts is their high elasticity, which allows them to withstand heavy loads while effectively minimizing the transmission of vibrations. In the automotive industry, for example, these mounts are crucial in reducing engine noise and improving passenger comfort. A study by the Society of Automotive Engineers highlighted that implementing premium rubber mounts can reduce vehicle interior noise by up to 50%. Additionally, they demonstrate excellent durability and resistance to environmental factors, making them ideal for outdoor applications in construction equipment, where exposure to harsh conditions is common. This combination of features positions rubber isolation mounts as essential tools for achieving operational excellence in various industrial applications.

| Industry | Application | Benefits of Rubber Isolation Mounts | Unique Features |

|---|---|---|---|

| Automotive | Engine Vibration Reduction | Improved Comfort & Reduced Noise | High durability and flexibility |

| Construction | Machinery Shock Absorption | Protection of sensitive equipment | Resistance to weathering and chemicals |

| Aerospace | Landing Gear Vibration Control | Enhanced safety and performance | Lightweight yet strong |

| Manufacturing | Machine Mounting | Stability and alignment | Customizable shapes and sizes |

| Electronics | Equipment Isolation | Efficiency and longevity of devices | Vibration dampening properties |

The application of rubber isolation mounts plays a crucial role across various industries, reflecting their versatility and effectiveness in vibration control. For instance, in the automotive sector, these mounts are vital for different applications such as suspension, engine mounts, and exhaust systems. According to market insights, the automotive bushing market is projected to experience significant growth, driven by the rising demand for innovative vibration isolation solutions.

The application of rubber isolation mounts plays a crucial role across various industries, reflecting their versatility and effectiveness in vibration control. For instance, in the automotive sector, these mounts are vital for different applications such as suspension, engine mounts, and exhaust systems. According to market insights, the automotive bushing market is projected to experience significant growth, driven by the rising demand for innovative vibration isolation solutions.

In shipbuilding, the anti-vibration market is estimated to reach $1,253 million by 2027. This growth reflects the industry's increasing recognition of the need for effective noise and vibration reduction technologies to enhance vessel performance and safety. The adoption of rubber isolation mounts in these applications not only prolongs equipment life but also improves operational efficiency.

Tips for industries considering rubber isolation mounts include evaluating the specific vibration frequencies of the applications to choose suitable materials, such as rubber or composite alternatives. Additionally, it is essential to prioritize regular maintenance and monitoring of isolation systems to avoid costly breakdowns, underscoring the benefits of vibration analysis for ongoing diagnostics and performance optimization.

Rubber isolation mounts are critical components in both the automotive and aerospace industries, serving distinct yet essential functions. In the automotive sector, these mounts typically reduce noise, vibration, and harshness (NVH), which has become increasingly important for consumer satisfaction. According to a report by the Society of Automotive Engineers, the effective use of rubber isolation mounts can lead to a reduction in NVH levels by up to 40%, enhancing passenger comfort. Automotive manufacturers are now investing heavily in advanced materials to optimize these mounts for weight reduction and durability, leading to overall improved vehicle performance.

In contrast, aerospace applications demand even stricter performance metrics due to the unique challenges posed by high altitudes and varying temperature ranges. Studies show that rubber isolation mounts used in aircraft can withstand temperatures between -55°C to +150°C and must ensure a vibration reduction of at least 50% during flight operations. The Federal Aviation Administration (FAA) emphasizes the significance of these mounts in maintaining structural integrity and passenger safety, creating a higher standard that drives innovation in materials and design.

**Tips**: When selecting rubber isolation mounts, always consider the specific operational environment they will be exposed to. Ensure compatibility with temperature fluctuations and material fatigue to maximize the longevity and performance of the mounts. Additionally, collaborating with suppliers who provide comprehensive testing data can aid in making informed decisions that align with industry standards.

When evaluating the cost-benefit of rubber isolation mounts in manufacturing settings, it is essential to consider both immediate expenses and long-term savings. These mounts are designed to reduce vibrations and noise, which can lead to machinery wear and tear. By investing in high-quality rubber isolation mounts, manufacturers can significantly extend the lifespan of their equipment, reducing the frequency and cost of repairs. The initial investment is often offset by the savings on maintenance and downtime, making it a financially sound choice for many industries.

Moreover, the integration of rubber isolation mounts can enhance operational efficiency. By decreasing vibrations, they help maintain precise tolerances in manufacturing processes, resulting in better product quality. This improvement not only leads to increased customer satisfaction but also minimizes waste. The ability to maintain a quieter work environment further contributes to employee comfort and productivity, creating a more conducive atmosphere for innovation and efficiency. When considering these factors, it becomes evident that the cost-effectiveness of rubber isolation mounts extends beyond their purchase price, positioning them as a valuable asset in modern manufacturing.

Rubber isolation mounts play a crucial role in construction and engineering, offering innovative solutions for vibration and shock absorption. In construction, these mounts are used to enhance the longevity and stability of structures by reducing the impact of vibrations from heavy machinery, traffic, or seismic activity. For instance, in high-rise buildings, rubber isolation mounts are strategically placed between floors and mechanical equipment to minimize the transfer of vibrations, ensuring a quieter and more comfortable environment for occupants. This application not only improves structural integrity but also extends the lifespan of essential building systems.

Additionally, the engineering sector employs rubber isolation mounts in the design of sensitive equipment and machinery. In industries such as aerospace and automotive, these mounts help protect critical components from the damaging effects of vibration. By isolating engines or sensitive instrumentation from the chassis or frame, rubber mounts significantly enhance performance and reliability. Innovations in rubber materials and design have allowed for greater customization, enabling engineers to tailor mounts that meet specific shock absorption and vibration isolation needs, resulting in safer and more efficient machinery.

This chart illustrates the unique applications and usage volume of rubber isolation mounts across various industries, highlighting their significance in sectors such as construction, automotive, aerospace, marine, and heavy machinery.