Automobile window lift rubber parts——SKY Rubber

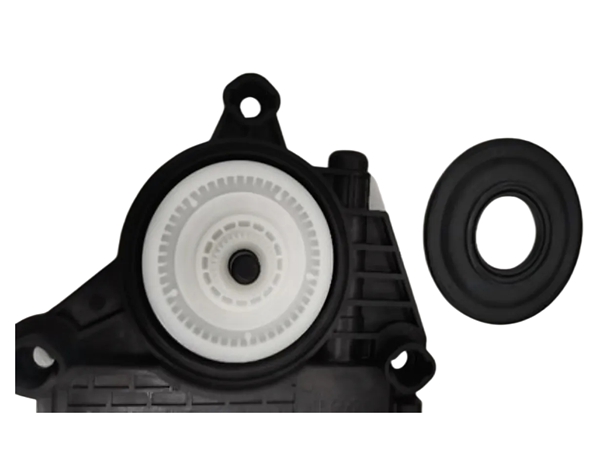

The Rubber Components for car window lifting are the key to ensuring a comfortable driving experience. Its excellent sealing performance effectively blocks wind, rain, dust, and external noise, creating a quiet interior space; High elasticity and flexibility ensure smooth lifting and lowering of car windows, reducing jamming and abnormal noise. At the same time, this component has excellent weather resistance and wear resistance, and can work stably in complex environments such as high temperature, severe cold, and humidity. It is not easy to age or deform after long-term use. In addition, it is precisely designed according to different vehicle models and perfectly adapted to the window structure, providing reliable guarantees for driving safety and quality improvement.

In the manufacturing of car window components, customers use PBT and TPV for cladding molding, but face the dilemma of material cracking and loosening after welding. Due to the frequent lifting and lowering of car windows, the looseness between components can produce harsh noise, seriously affecting the driving experience and product reliability. The core of this problem lies in the poor compatibility of the molecular structures of the two materials. Under the effects of welding thermal stress and long-term vibration, the interfacial bonding force is prone to failure.

The SKY Rubber engineering team conducted in-depth analysis of material properties and innovatively selected NBR rubber and PBT for encapsulation molding. By optimizing the material formula and process parameters, the molecular chains of NBR rubber and PBT are deeply entangled and tightly interlocked, forming strong chemical and physical bonds.

After testing, this solution not only completely eliminates the noise of car window lifting, but also significantly improves the welding strength of components - in high-temperature and high-frequency vibration environments, there are no signs of looseness at the component connections, and the service life is longer than the original solution. Solved customer pain points from the root, providing reliable guarantees for the high performance and long lifespan of automotive components.