Customized solution for rubber shell of electronic atomizer-SKY Rubber

As a world-renowned high-tech company in atomization technology, the company's core business is the research and development and sales of electronic atomizers and key components. In 2018, with the continuous upgrading of consumption levels, its original products with pure plastic shells could no longer meet the increasing needs of consumers.

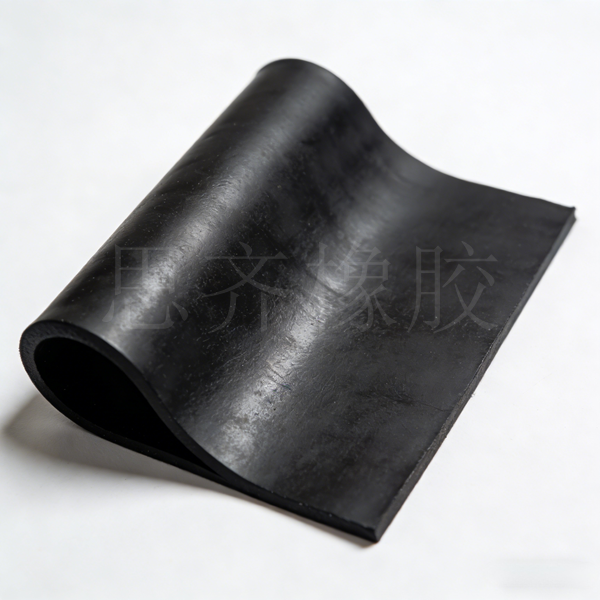

In this context, the company developed a new type of electronic atomizer. This product not only looks cool and is more in line with consumers' aesthetics, but also has the "three-proof" functions of waterproof, dustproof, and drop-proof. However, due to the irregular shape of the product and the need for skin-friendly and anti-slip protection around it, the realization of these key functions mainly relies on Rubber Parts, which places extremely high demands on the research and development and customization capabilities of rubber product factories.

The company contacted SKY Rubber after being introduced by the supplier. Recognizing SKY Rubber's outstanding advantages in R&D, design and customization, the company hoped that it could solve this problem.

In response to the demand, SKY Rubber took prompt action and adopted the industry's advanced high-toughness plastic-coated zinc alloy multi-material composite rubber technology, UV modified surface treatment technology, etc. Through the application of these technologies, the rubber parts finally created perfectly meet all requirements: the product surface is smooth and not easily contaminated by dust; it has excellent waterproof, dustproof and drop-proof performance; it feels smooth and has a beautiful appearance, and it also meets FCM food-grade safety standards.

The company was impressed by the customized solution provided by SKY Rubber for this electronic atomizer. This cooperation not only helped the company seize the global electronic atomizer market in advance, but also made SKY Rubber the core supplier of rubber parts for the company.