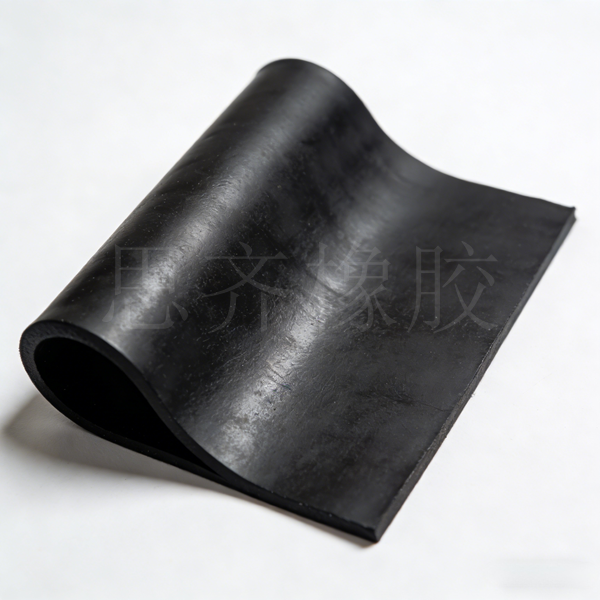

Introduction to Liquid Silicone Rubber (LSR) -SKYRUB

Molded liquid silicone rubber ( LSR ) is a high-performance type of silicone rubber. Compared to condensation-type silicone rubber, it produces fewer byproducts during vulcanization, has less shrinkage, can be vulcanized more deeply, and exhibits better high-temperature performance. Furthermore, the LSR process is simple and inexpensive.

LSRs typically consist of a base adhesive , polymethylvinylsiloxane raw rubber, a crosslinking agent, polymethylhydrosiloxane, and a catalyst, a complex of transition metals (platinum, nickel, rhodium , etc.). Depending on the application, other fillers such as silica, iron oxide, titanium dioxide, and carbon black can be added. Adding silicone resin can produce transparent LSRs .

![]()

Performance characteristics :

LSR has excellent electrical insulation properties, aging resistance, high mechanical strength, good elasticity, quick and convenient molding, no reaction by-products, non-toxic and odorless, wide operating temperature range, safety and hygiene, and strong product extensibility.