Rubber Overmolding Solutions——SKY Rubber

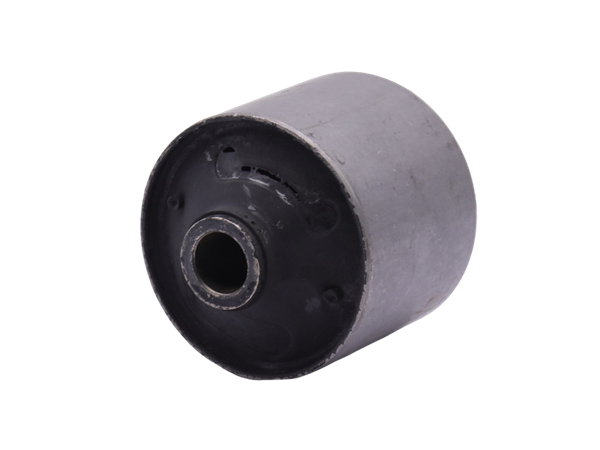

Rubber overmolding is an advanced manufacturing process in which plastic, metal and other substrates are cleaned and pre-treated and accurately placed in the mold cavity. Liquid silicone rubber or other rubber materials are then injected to make it flow evenly around the substrate and fill the mold. The rubber is cured by heating, ultraviolet irradiation and other methods, and a strong rubber layer is formed on the surface of the substrate by physical winding and chemical cross-linking. This gives the product excellent anti-slip and wear-resistant properties, a comfortable touch experience, good waterproof sealing effect and a unique appearance. It is widely used in automotive interiors, electronic equipment housings, medical device handles and other fields, providing solutions for improving product functionality and aesthetics.

SKY Rubber has been deeply engaged in the field of rubber overmolding technology. The composite manufacturing solutions designed and developed by it cover a variety of material combinations, including rubber + plastic, rubber + metal, rubber + glass, rubber + ceramics, rubber + cloth, rubber + sensors and rubber + PCB, etc. The technical solutions and production processes are highly mature and can accurately respond to customers' personalized customization needs.

Relying on the advantages of coating technology, the product expands multiple feasible solutions for customers on the design side: strengthening the mechanical structure through the integration of material properties (such as the impact-resistant buffer combination of metal substrate and rubber layer), integrating waterproof , anti-slip, insulation and other functional characteristics (such as rubber coating protection of PCB boards of electronic equipment); realizing "integrated molding" on the production side , reducing traditional assembly processes, Improve material utilization.

Currently, the technology is widely used in the automotive industry (anti-slip coating for steering wheels, weather-resistant design for seals ), medical devices (antibacterial and anti-slip treatment for surgical instrument handles), consumer electronics (waterproof packaging for sensors, buffer structure for mobile Phone Cases), home appliances (ergonomic design for kitchen utensil handles) and household items, etc., using mature technology chains to provide full-process solutions from material adaptation to function realization for different industries.